Services

Engineering

Engineering

Calculation of an individual exhaust header for your project

Calculation of valve spring pressures for specified RPMs / boost levels.

Design of parts according to your individual specifications.

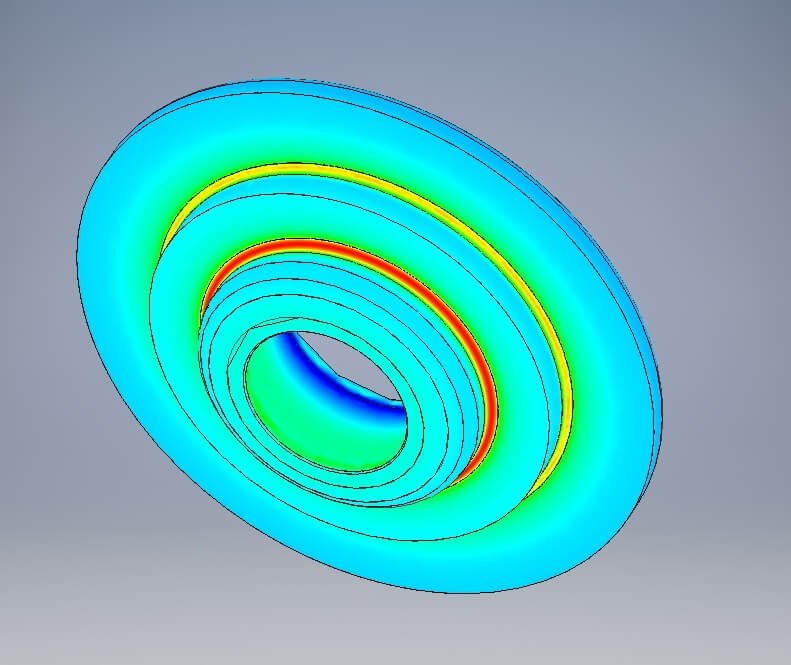

Exhaust header calculation

The purpose of every exhaust manifold is to optimise the power and torque curve of the engine. To achieve this goal, you need a manifold with optimised and tuned manifold tube lengths, diameters and routing. Determining these characteristics for your individual engine is the goal of the exhaust header calculation. Based on the calculated data, a manifold with optimal cross-section ratios and pipe lengths can be made that will achieve a very good result right from the start!

Services

Engineering – Exhaust header calculation

additional services:

Based on the results of the exhaust header calculation, an optimised, individual exhaust manifold can be made for your vehicle at the first attempt. Extensive tests on the dyno are not necessary, no matter how unique your engine is!

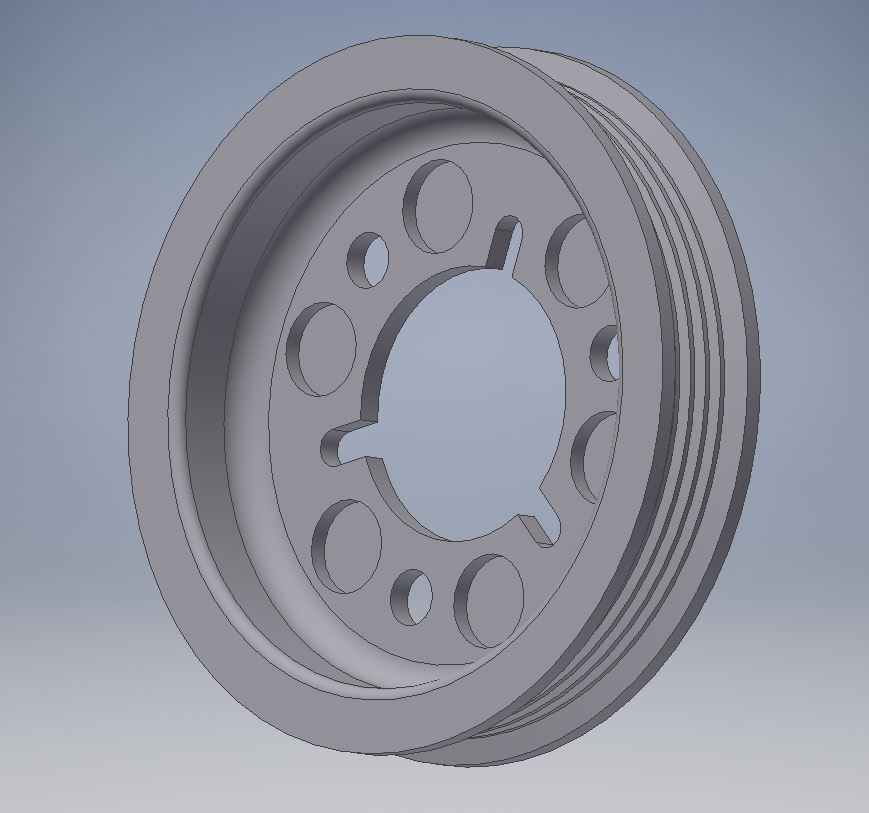

Valve train design & calculation

When it comes to achieving the highest possible engine rpms, power or boost levels, it is essential to know the required valve spring pressures. The required values can be calculated with the aid of the valve spring calculation.

Services

Engineering – Valve train design & calculation

additional services:

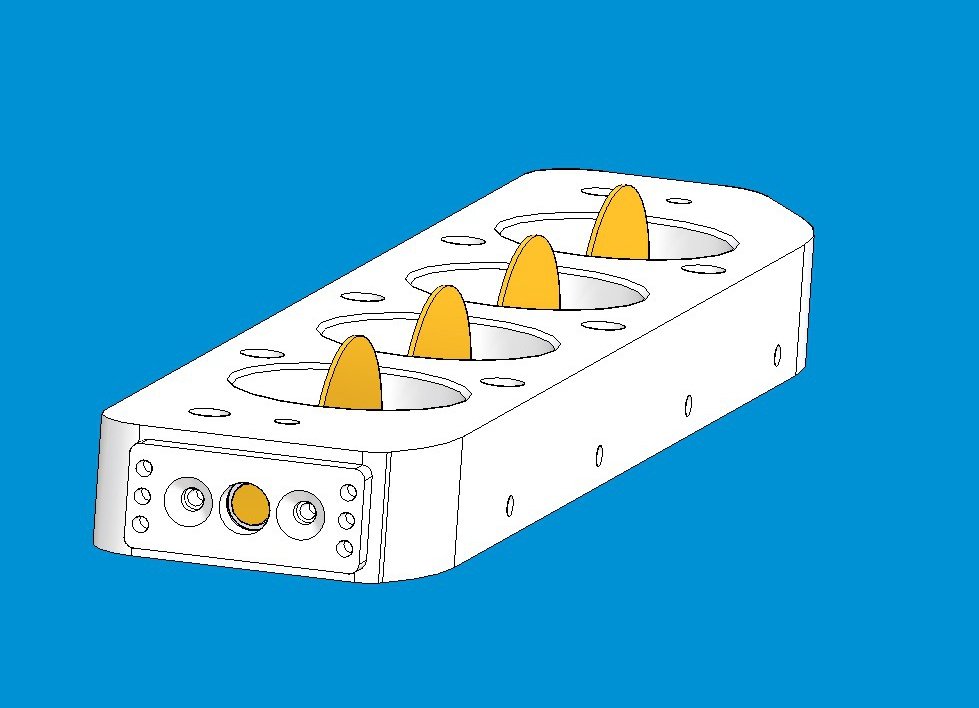

3D CAD design

Computer Aided Design (CAD) describes the computer-aided technical drawing of parts with the help of dedicated software. Precise designs and drawings are required by the manufacturing industry.

As a mechanical engineer, I first implement your requirements and ideas in a CAD design.

Afterwards, this forms the basis for a production-ready drawing or a 3D data set / model for manufacturing.

Thanks to many years of experience with various CAD systems, I can help you in a quick and uncomplicated way!

Services

Engineering – 3D CAD design

WANT TO MAKE A DIFFERENCE?

Hello,

Can you help get more HP for our Peugeot 206?

1,6 16V TU5J4